EPS that goes full circle:

Conserving resources in production.

Saving resources in the application.

Conserving resources in production.

Saving resources in the application.

The future lies in the cycle

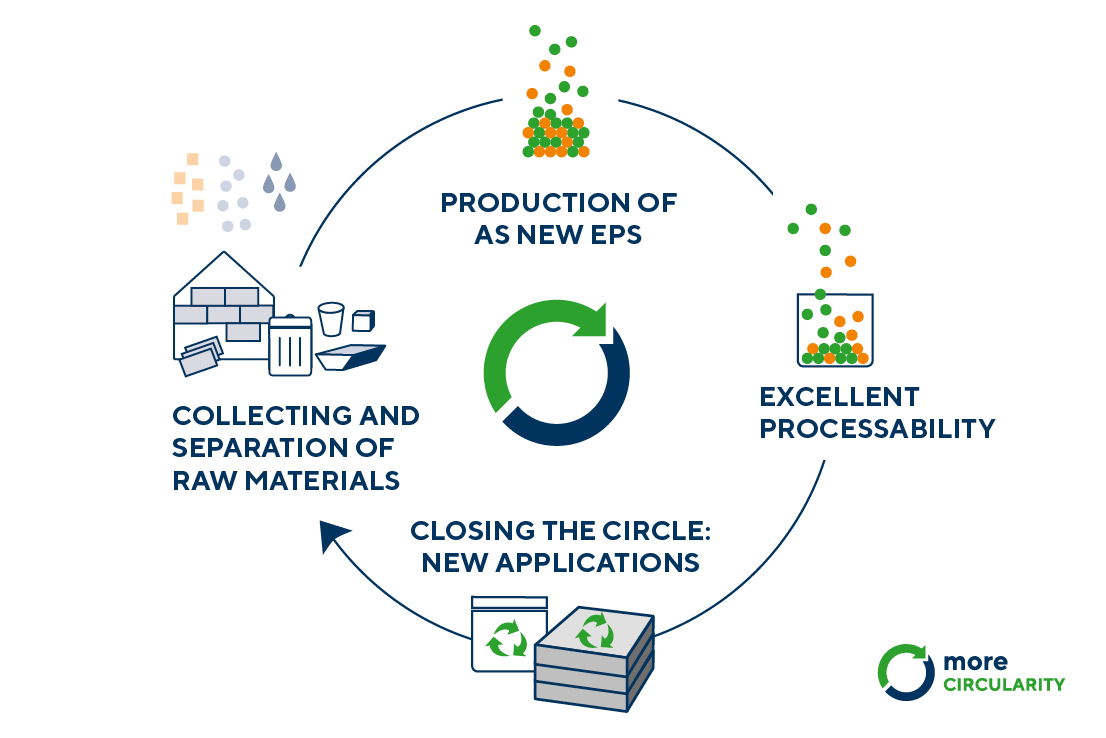

EPS OUT OF EPS

What if we can upcycle old EPS applications back into EPS? Making them as good as new, and with all the strengths and functionalities that we associate with EPS? The result is an EPS cycle in which we use fossil-based primary energy only once, bound in EPS for many generations of the product. Enabling EPS to not only protect value and the climate when it is used, but also when it is produced: with outstanding efficiency in how energy and fossil resources are used.

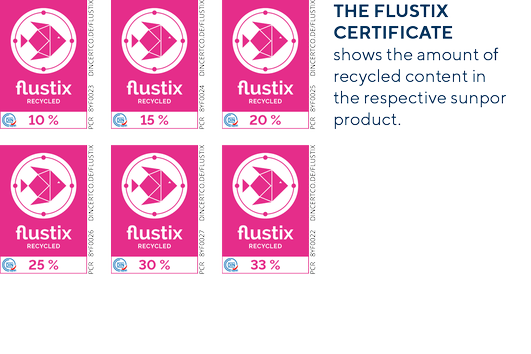

In our development lab, we at sunpor have created upcycled EPS that meets these requirements: Based on high-quality, flustix-certified recycled material. With a growing variety of types, which also includes the super insulator lambdapor®. And as the first manufacturer of industrial quantities.

What if we can upcycle old EPS applications back into EPS? Making them as good as new, and with all the strengths and functionalities that we associate with EPS? The result is an EPS cycle in which we use fossil-based primary energy only once, bound in EPS for many generations of the product. Enabling EPS to not only protect value and the climate when it is used, but also when it is produced: with outstanding efficiency in how energy and fossil resources are used.

In our development lab, we at sunpor have created upcycled EPS that meets these requirements: Based on high-quality, flustix-certified recycled material. With a growing variety of types, which also includes the super insulator lambdapor®. And as the first manufacturer of industrial quantities.

COMPOSTABLE

Biodegradable polymer foams for special applications are another part of the journey towards a sustainable future. sunpor® bio Infill is one way that we have embarked on this journey.

Technical Details >

Biodegradable polymer foams for special applications are another part of the journey towards a sustainable future. sunpor® bio Infill is one way that we have embarked on this journey.

Technical Details >