De

En

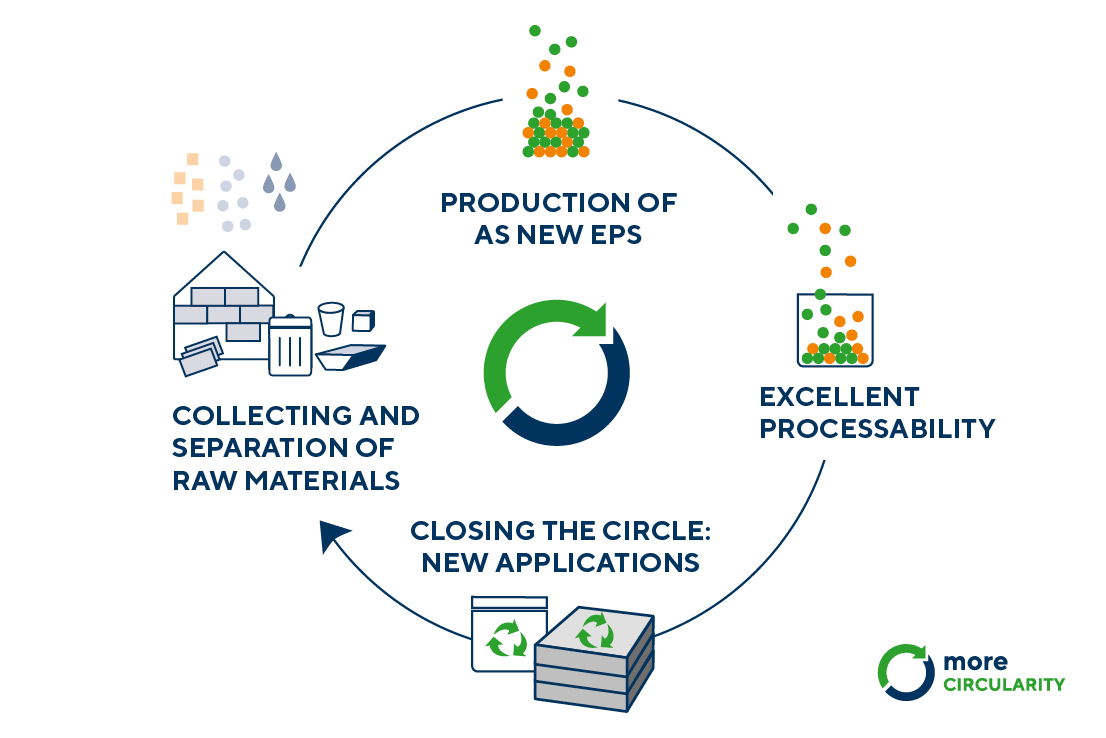

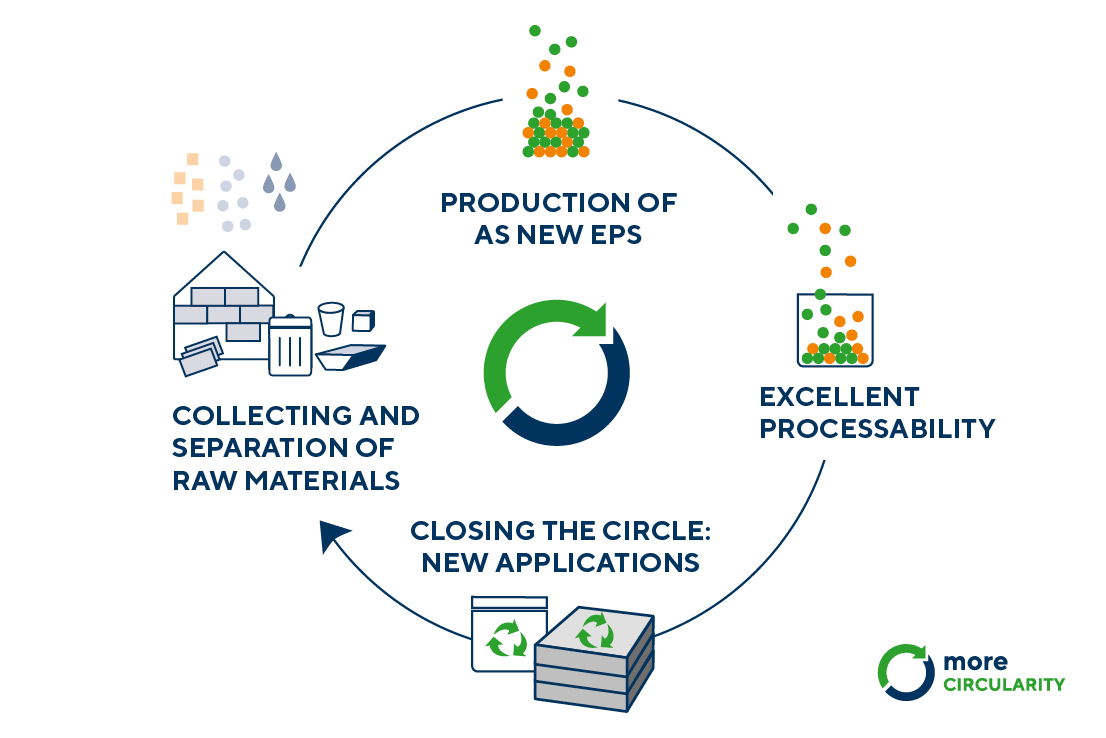

The future lies in the cycle

New product line

"more circularity"

EPS that goes full circle:

Conserving resources in production.

Saving resources in the application.

Conserving resources in production.

Saving resources in the application.

As a pioneer of the EPS circular economy, sunpor is taking an important step for the future with its new "more circularity" product line. sunpor is the first manufacturer to produce innovative EPS granulates with recycled content on an industrial scale and to develop biodegradable special foams. Audited and certified by the independent auditors of flustix®.

98% air, 100% recyclable

EPS consists of 98% air and is 100% recyclable. Highly insulating, lightweight and affordable, EPS is an indispensable part of the global fight against climate change. For building insulation made of EPS significantly reduces the energy required for heating and cooling living space.

98% air, 100% recyclable

EPS consists of 98% air and is 100% recyclable. Highly insulating, lightweight and affordable, EPS is an indispensable part of the global fight against climate change. For building insulation made of EPS significantly reduces the energy required for heating and cooling living space.

"We aim for EPS that, after decades of use, becomes new EPS again and again in order to save energy and fossil resources. Minimum ecological footprint but maximum climate-friendly effect," Roman Eberstaller, CEO of sunpor, states the direction for the future.

With repor® and Lambdapor® R10, sunpor brings the upcycling principle to practice. The use of recycled material saves energy and fossil resources in both application and production. A first step has been taken, more will follow.

Find out more about "more circularity"

With repor® and Lambdapor® R10, sunpor brings the upcycling principle to practice. The use of recycled material saves energy and fossil resources in both application and production. A first step has been taken, more will follow.

Find out more about "more circularity"