De

En

Resources, climate and comfort:

why sunpor EPS is part of the solution

Because building insulation and packaging made of sunpor EPS saves many times the energy needed to produce it. And this all the more in a future EPS circular economy in which used EPS is recycled to make new EPS. This is what we at sunpor are committed to. As the world’s leading technological manufacturer of EPS granules. With personal support for processors. Working passionately to achieve a sustainable future.

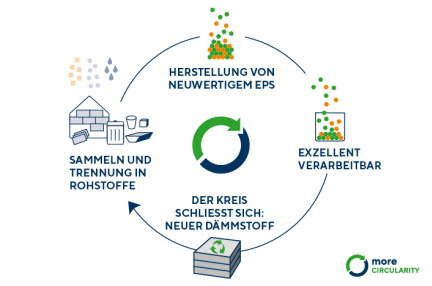

Not only have EPS insulation boards saved valuable (heating) energy in houses for decades, but they also form the basic material for insulation that is as good as new. sunpor is committed to having an EPS circular economy. The newly developed CreaSolv® process has put this goal within striking distance.

more

EPS is a material with contrasting properties: It is lightweight and yet robust. It keeps heat in when it is cold, and keeps it out when it is hot. It only needs a small amount of fossil resources when being made in order to save such resources many times more when it is used. The fact that EPS is able to overcome old contradictions is due in no small part to sunpor’s innovative work. Highly developed EPS provides a route to applications that are convenient, economical and environmentally friendly in equal measure. After all, future solutions depend on being able to combine past contradictions in an innovative way.

more

EPS – the raw material

EPS: highly diverse, specific uses

Insulation that keeps both the heat and the cold outside – and allows the walls to “breathe”. Helmets that not only provide lightweight and efficient protection, but can also have a trendy look. Packaging that is as light as a feather but as strong as a bull...

EPS is so much more than ‘polystyrene’. At sunpor, we have turned it into an innovative material that turns clever ideas into successful applications: highly functional, diverse and highly efficient when it comes to costs and the use of raw materials. This is why EPS from sunpor is the right choice.

Insulation that keeps both the heat and the cold outside – and allows the walls to “breathe”. Helmets that not only provide lightweight and efficient protection, but can also have a trendy look. Packaging that is as light as a feather but as strong as a bull...

EPS is so much more than ‘polystyrene’. At sunpor, we have turned it into an innovative material that turns clever ideas into successful applications: highly functional, diverse and highly efficient when it comes to costs and the use of raw materials. This is why EPS from sunpor is the right choice.

sunpor applications

suncolor circolor® 100

Helmets that protect more than your head more